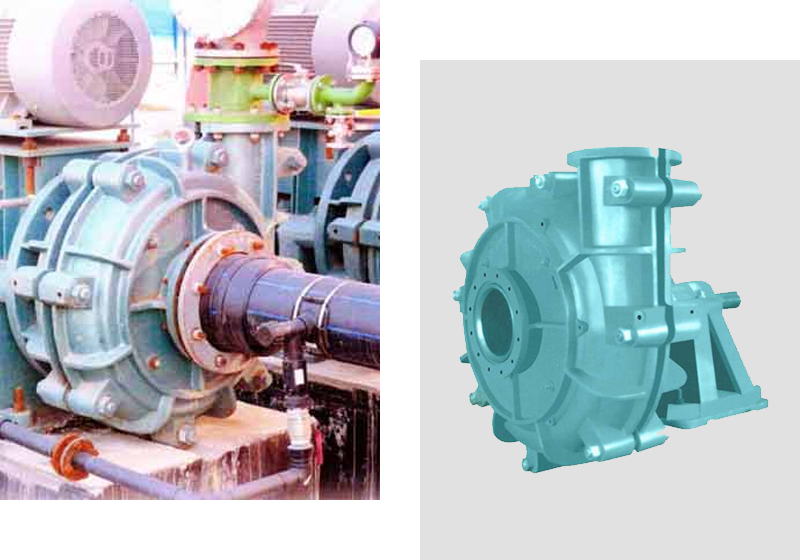

Heavy Duty Slurry Pumps

Capabilities & Design Features

Heavy Duty Slurry Pumps are designed for long life, efficient operation, and ease of maintenance resulting in a lower total cost of operation.

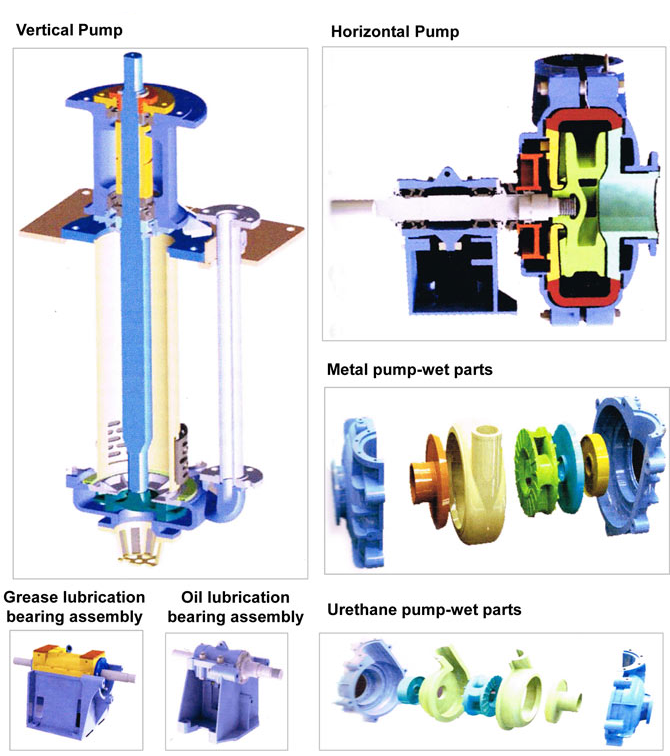

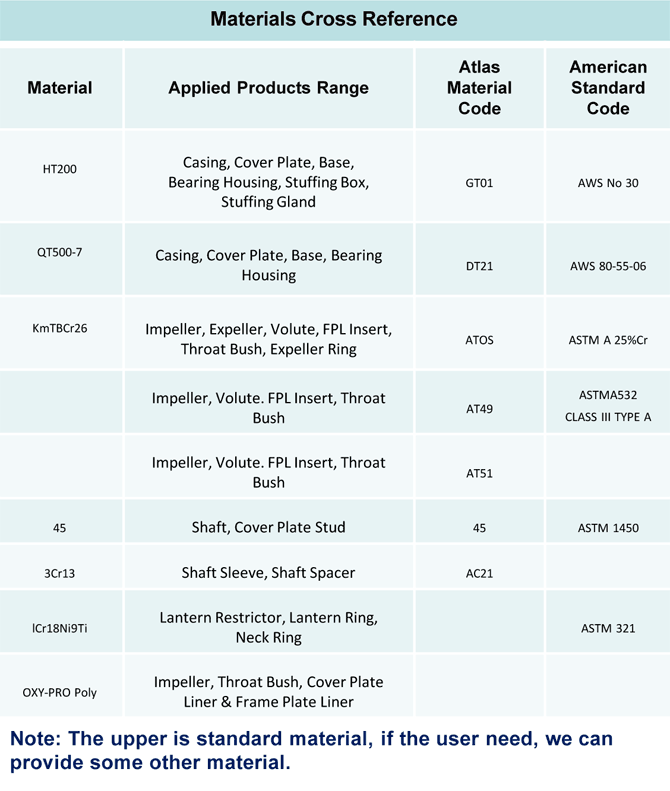

Pumps are available in either OXY-PRO Poly or Metal lined utilizing Abrasive and Corrosive Resistant Materials

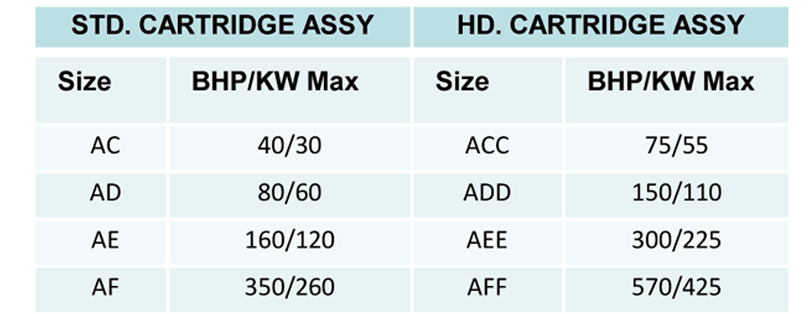

An Optional heavy duty bearing assembly is available from UMA for applications where additional power required.

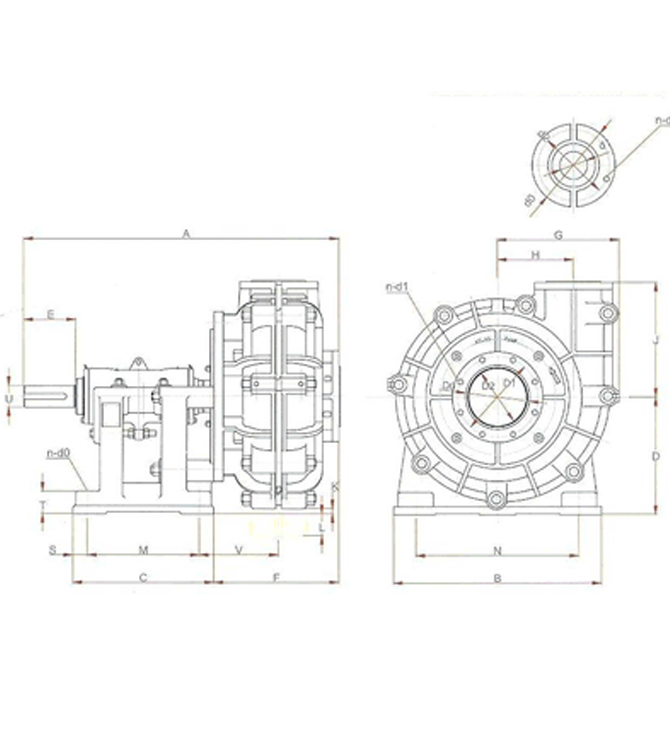

Cartridge Bearing Assembly and Shaft

The shaft is designed with a short overhang to:

Reduce shaft deflection.

Minimize vibration

Provided with hardened shaft sleeve to protect the shaft.

Optional dimensionally interchangeable heavy duty

bearing cartridge assemblies

Cartridge assembly is retained on a one piece frame

Grease purged piston rings to help seal contaminates

out of bearing housing.

Impeller

Enclosed impellers to maximize efficiency

Pump out vanes on both shrouds

Minimizes recirculation

Reduces stuffing box pressure

OXY-PRO or Hard Metal wet ends

Interchangeable hard metal and

OXY-PRO Impellers

Cast-in impeller threads to protect shaft

Impeller clearance set by moving cartridge assembly.

Double casing with radial split outer casing

Ease of assembly and disassembly of wet end.

Optional ductile iron construction for higher working pressures.

Removable liners are positively attached with fasteners.

Dynamic Seals

Reduces or eliminates need for seal water.

Reduces sleeve wear and possible bearing failure.

Removable Liners

Liners are positively attached utilizing studs

UMA OXY-PRO®

Exceptional wear life and chemical resistance for your pumps

Reduce Costs

Cost life effective & Reduced stock holding due to extended service life

Chemical Resistance

Highly resistant to swelling from chemical attack.

Eliminate Downtime

Extended life OXY-PRO of wet end parts eliminates pump stoppages.

Increase life

OXY-PRO has increased pump wet end life up to ten times (depending on application)

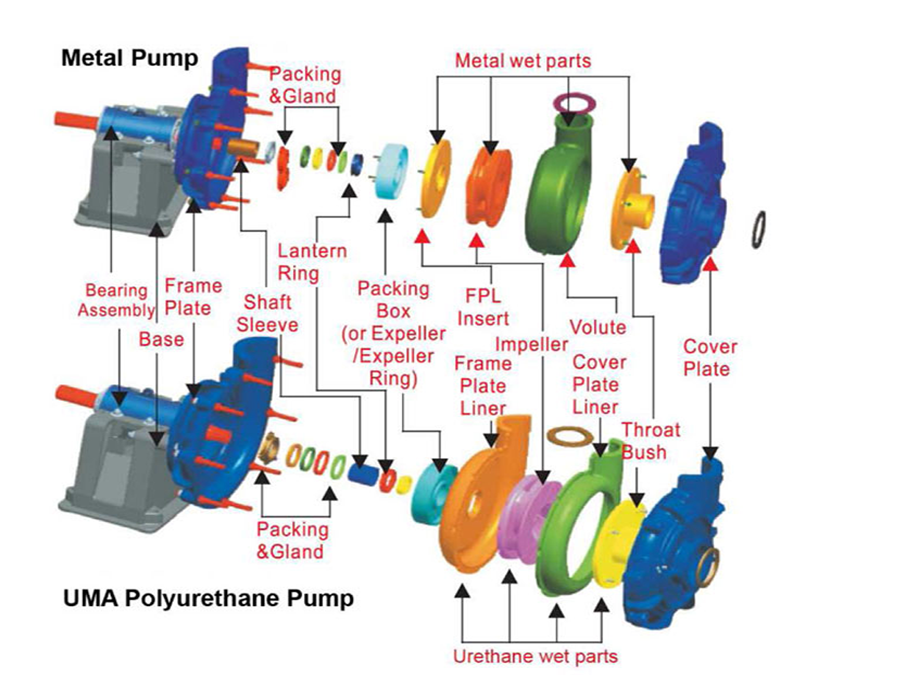

Pump configuration

The pump liner and impeller material have

interchangeable wear part combinations.

Liners and impellers for hard metal and OXY-PRO lined

pumps have common dimensions and are

interchangeable within the same pump size.

Frame supports the bearing cartridge which includes

grease lubricated taper roller or cylindrical bearings.

Bearings are located on a large diameter shaft designed

to minimize overhang and deflection.

For conventional packed box and lantern ring

construction, sealing water must be provided at a

minimum of 10 PSIG above discharge pressure to insure

positive flow.

Where suction conditions allow. UMA’s expeller seal

can eliminate the need to supply water to the stuffing

box. Where high suction pressures or series pumping is

desired other methods of sealing must be utilized.

Expeller and expeller ring are constructed from Hi Chrome material.

Shaft sleeve material is 420 SS hardened to 550 Brinell

to protect the shaft from wear.

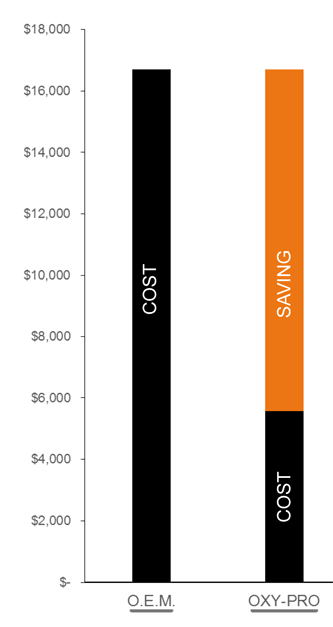

Cost Savings

The recorded running hours between replacement of chrome steel and rubber wet end parts averaged 750 hours, at a cost of $3,709 per set.

UMA OXY-PRO®

wet end parts lasted 7,500 hours (10 times longer) at a cost $5,565 per set.

The cost of rubber or steel parts to run

7,500 hours was $37,090. The mine Has saved $31,525 on just one pump in 10 months.

Components Structure & Graphs

Contact Us

Urethane Manufacturers of Australia Pty Ltd (UMA) has proudly emerged as the unrivaled leader in Australasia’s mineral processing industry. With a rich history spanning four decades, UMA has become synonymous with quality, reliability, and innovation in the supply of Replacement Parts for Mineral Process Equipment, Accessories, and Coatings.