Hydrocyclones

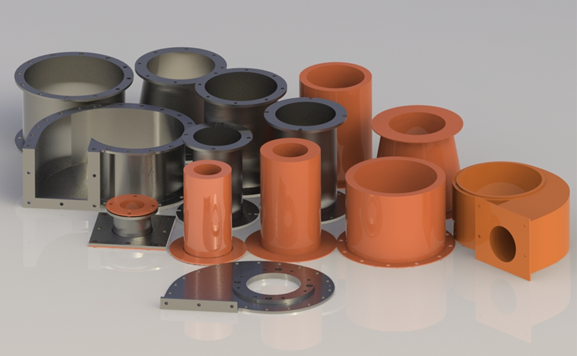

UMA CYCLONE LINERS

SAVE 60% ON OPERATING COST

At UMA, we specialize in manufacturing replacement liner parts from our superior wear resistant OXY-PRO® to fit all brands of hydrocyclones

We can manufacture liner components for cyclones supplied by all leading hydrocyclone original equipment manufacturers including Weir (Warman & Cavex), Krebs (GMax and Standard configurations), Hydrotec, Multotec, Linatex, AKW and Mozley.

Application

UMA offers a full product line that meet various needs of many

industries.

OXY-PRO® cyclones liners provide an highly

efficient, cost effective, low-maintenance way to separate the

material flowing through the system

Minerals

• Minerals

• Coal

• Hardrock Mining

• Alumina

Industrial

• Plastics Recycling

• Industrial Wastewater

• Potable Water

• Chemical & Petrochemical

• Food Pulp & Paper

• Washing Groundwater Remediation

• Refining

Cyclone technology

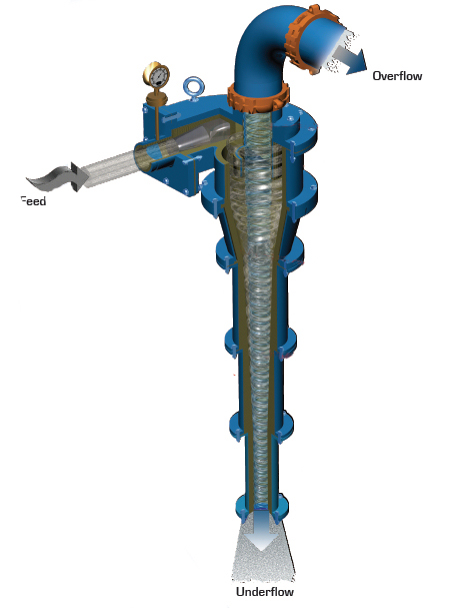

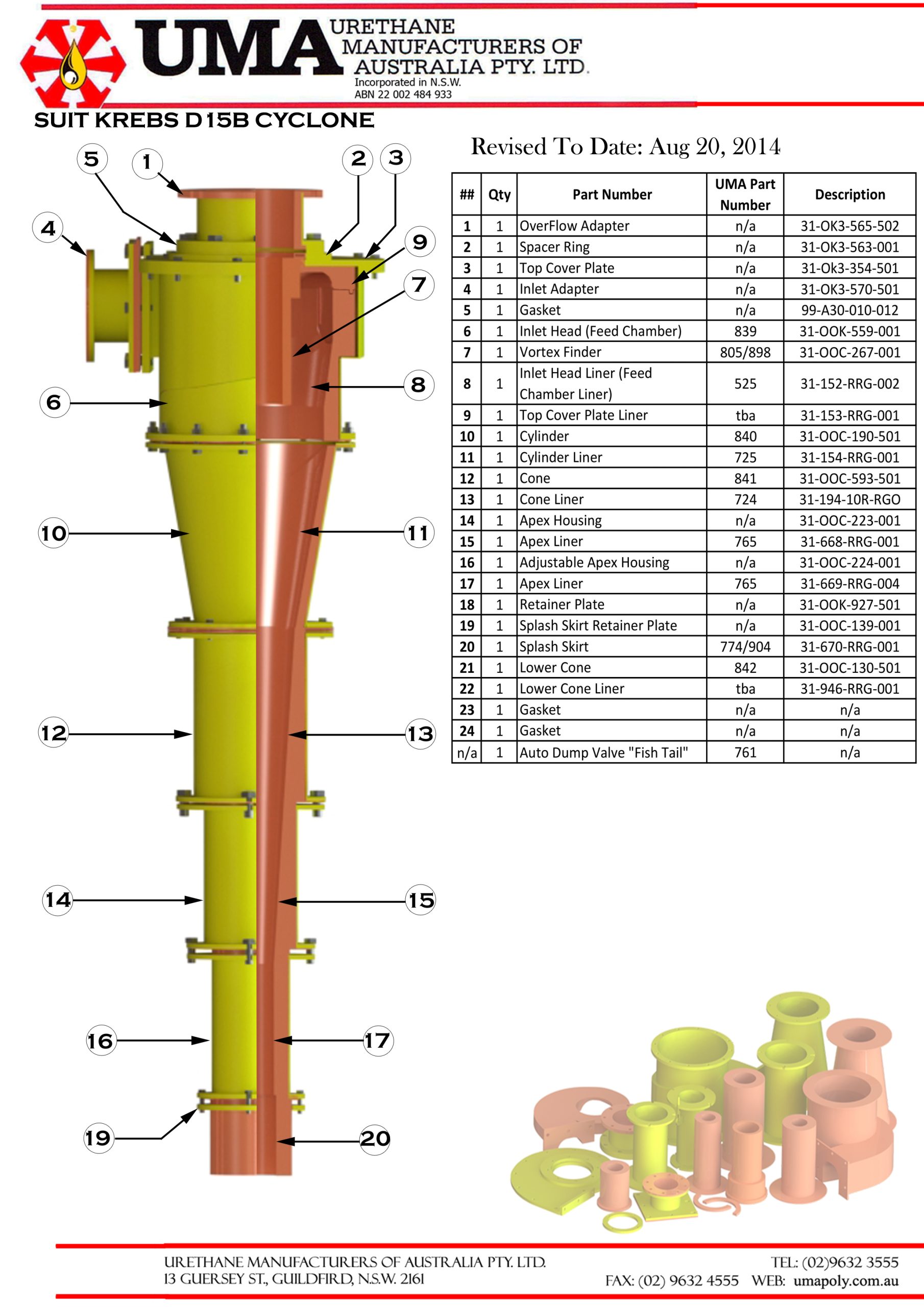

Cyclone uses centrifugal force which is caused by the flow through the inlet branch being tangential to the feed box. Naturally, the higher the inlet pressure the greater the rotational speed and the greater the centrifugal force, which is commonly many times that of gravity.

Solids are flung to the wall of the cyclone cone and spiral down to the spigot. The bulk of the liquid spirals upwards and leaves the cyclone through the vortex finder, the fraction leaving through the spigot being determined by the spigot to vortex finder relationship. The only solids to escape with the bulk of the water are the particles which are so fine that the entrainment or drag forces are not overcome by the centrifugal forces.

Thus, for any given inlet pressure/rotational speed there is a ‘cut’ size at which the drag and centrifugal forces are in balance. Particles finer than this cut size are dragged with the bulk of the liquid through the vortex finder, and particles coarser than the cut size report to the spigot.

UMA’s cyclone styles

To suit Weir-Warman

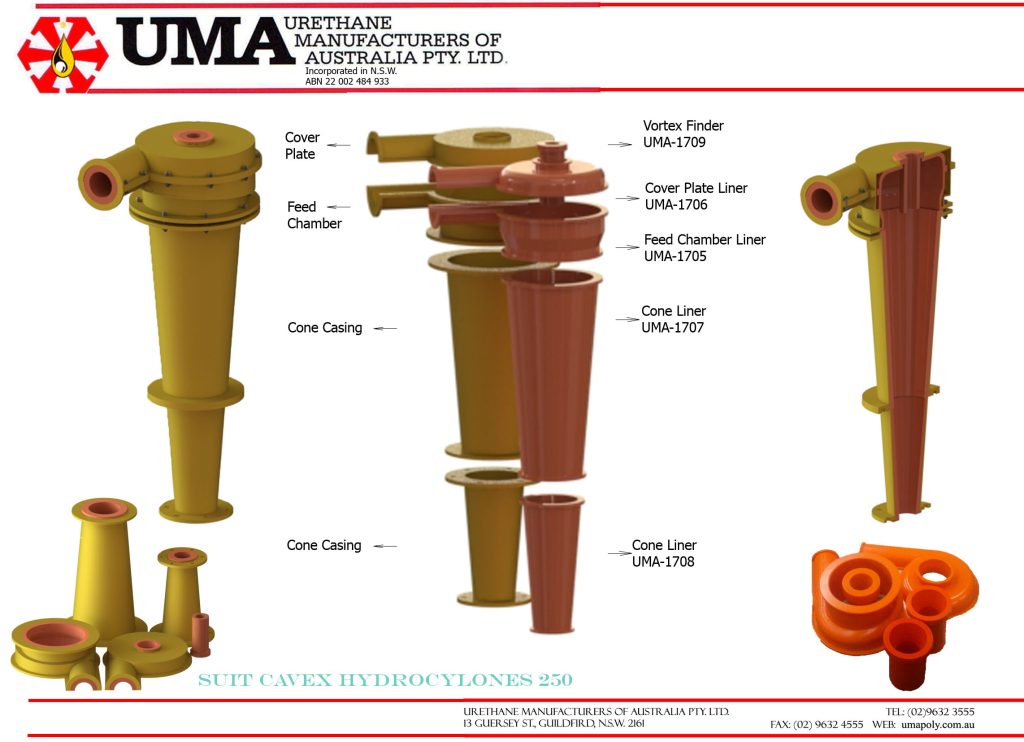

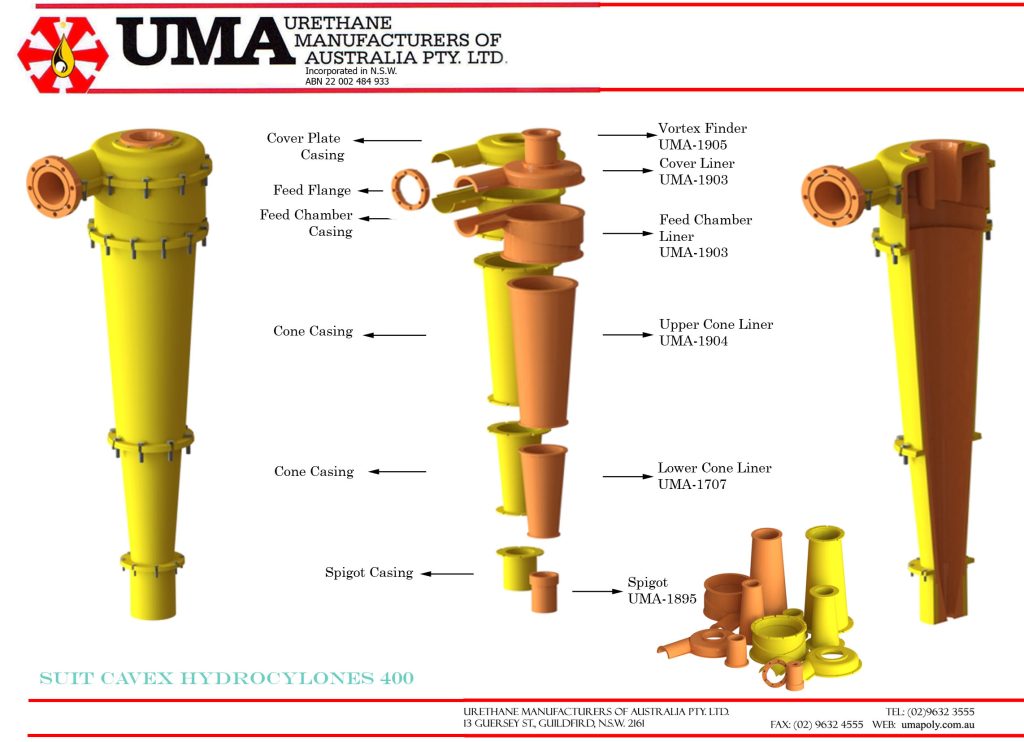

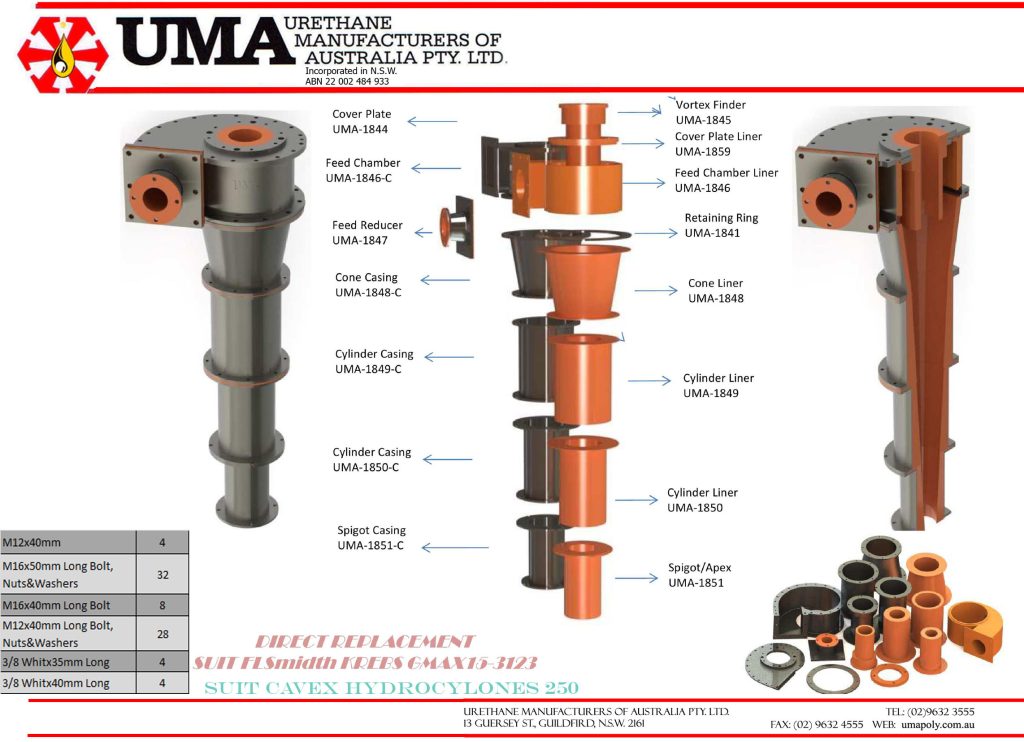

To suit Cavex (CVX)

• 100mm Cyclone Liners

• 150mm Cyclone Liners

• 250mm Cyclone Liners

• 400mm Cyclone Liners

To suit CE , CEL

• 4" CE 10 ° Cyclone Liners

• 10" CE 10 ° Cyclone Liners

10" CE 20 ° Cyclone Liners

To suit FLSmidth

To suit Linatex

• To suit G4 150 to 500 Hydrocyclones 10°, 15° & 20° Cone angles

To suit Krebs gMax

• Cyclone Casings gMAX

• Cyclone Liners gMAX 4U

• Cyclone Liners gMAX15-3123

Dump Valves “Fish Tail” Operated Cyclones

Have the following features:

Deliver the same underflow density, regardless of uncontrolled variation in solids content in the cyclone feed

Wll readily handle unexpected tramp oversize in the feed, without plugging

Produce a very high underflow density, essentially water and slime free, without being operated in ‘roping’ condition

Very simple to vary the underflow density as desired, without using troublesome and expensive mechanical or hydraulic adjustable spigot arrangements

Require a much lower spigot maintenance.

The OXY-PRO® Fishtail Cyclone liners meets all of these requirements

UMA Products

Our extensive range is used widely by Professionals engaged in Mining, Manufacturing and Repair. Whatever your application, you will find UMA superior quality will meet your most demanding requirements.

UMA Hydrocyclones

Cyclone liners, vortex finders, transition pieces and apexes fabricated from solid OXY-PRO® urethane perform three to four times longer than rubber linings and more than ten times longer than steel and are much lighter and easier to handle than steel.

Customer Testimonials

Contact Us

Urethane Manufacturers of Australia Pty Ltd (UMA) has proudly emerged as the unrivaled leader in Australasia’s mineral processing industry. With a rich history spanning four decades, UMA has become synonymous with quality, reliability, and innovation in the supply of Replacement Parts for Mineral Process Equipment, Accessories, and Coatings.